Polyamide 11

White, light-transmissive, additively manufactured parts for strong plastic prints are characterised by high impact strength and elongation at break. They do not crumble even under the highest mechanical load. They have a higher temperature resistance compared to PA 12 and have almost constant mechanical properties over a wide temperature range.

100% proven quality and 0% CO2e

PA 11 is a biobased material (castor oil) with a smaller carbon footprint compared to petroleum-based polymers. Following our Responsible Manufacturing purpose, we have implemented optimisations to reduce the carbon footprint of the PA 1101 Climate Neutral production process and invest in Gold Standard climate protection projects to offset unavoidable greenhouse gas emissions. Carbon neutral material comes with proven quality and material composition. Customers receive a certificate confirming the accuracy of the calculation and offsetting.

The material is also available as PA 1101 without carbon offsetting.

Typical mechanical properties

Tensile modulus 1600 MPa Tensile strength 48 MPa Elongation at break 45% Thermal properties

Melting temperature (20°C/min) 201°C Heat bending temperature (1.80 MPa) 46°C Heat bending temperature (0.65 MPa) 180°C

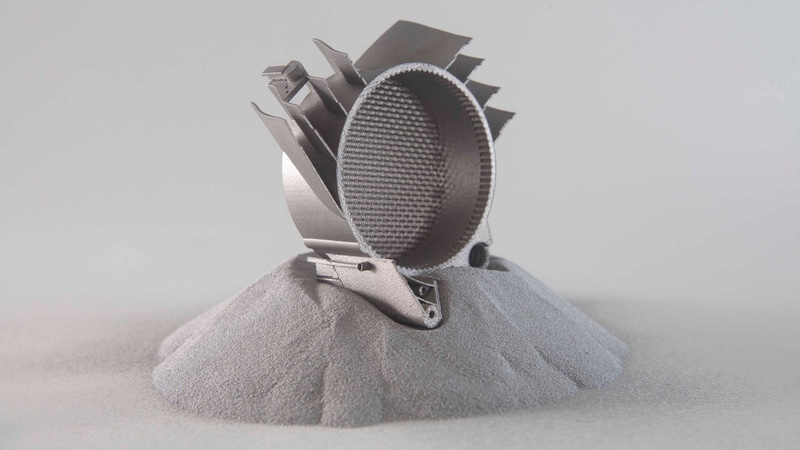

Metal Powders

We can create prototypes with the following metal powders:

- CpTi grade 1

- CpTi grade 2

- Ti-6Al-4V grade 5

- Ti-6Al-4V grade 23

- Ti-6Al-2Sn-4Zr-2Mo

- Ti-5Al-5V-5Mo-3Cr

- Ni Alloy 718

- Ni Alloy 625

- Al-Si7-Mg (F357)

- Al-Si10-Mg

- CoCrMo

- 316L Stainless Steel

- M300 Stainless Steel

- 17-4 PH Stainless Steel

- remanium star® CL

- rematitan® CL